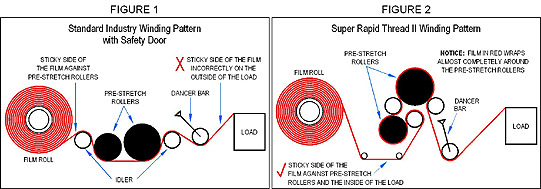

The

Super Rapid Thread ll

film carriage is patent pending and is the most innovative

carriage design to date. In the past, most manufacturers

decided to use easy thread safety doors for the ease of

film threading and safety. This reduced the “film-to-pre-

stretch roller” contact area as indicated in figure

1 (Industry Winding Pattern With Safety Door). In addition

to this, the idler rollers on the doors often fell out of

alignment. These two issues increased what the industry

refers to as film slippage.

People didn’t pay much attention to this in the past,

though it could add up to thousands of dollars, often doubling

film usage. Due to the increasing cost of stretch film,

people started paying a lot more attention to their pre-stretch

values and were astonished to discover huge differences.

This is the inspiration for the

Super

Rapid Thread ll.

The Super Rapid Thread II

has:

The largest film to pre-stretch roller contact area of any

other machine on the market

Only

one floating nip roller on the access door that automatically

aligns every time you

close the door

4

nip/idler rollers are rigidly fixed (cannot move)

No

spring-loaded nip rollers

Patent

pending threading device for ease of threading

One

of a few carriages on the market that correctly puts the

sticky side of the film

against both the pre-stretch

rollers and the inside of the load

Safety

electrical interlock - shuts the power off when the carriage

access door is open

Carriage

anti-fall device. If the chain breaks the carriage can’t

fall

Carriage

descent plate. Stops the carriage descent if an obstacle

is detected

The film carriage is the most critical device on

the machine. It needs to be well designed and in the case

of older models well tuned.

The SUPER RAPID THREAD II

requires no tuning!!

The film carriage is the most critical device on

the machine. It needs to be well designed and in the case

of older models well tuned.

The SUPER RAPID THREAD II

requires no tuning!!